In this post has been given the reliability About Why are digital kitchen scales so unreliable ?. A kitchen scale is made specifically to weigh different items that are used to make a variety of recipes.It can accurately measure liquids, dry goods, chopped or mixed materials. In this manner, you are not limited to using pounds or kilogrammes.

What is a kitchen scale?

Items are weighed on a scale to determine their weight.

In order to ensure that the components are utilised exactly as specified in the recipe, they are frequently used in cooking.

Why are digital kitchen scales so unreliable?

There aren’t many things more annoying than weighing something twice and getting two completely different outcomes.

If you’re weighing anything at all, it’s likely because you require a precise measurement and are thus unable to trust your digital scale in any way.

It is crucial to have a trustworthy scale that is accurate. In practically any firm, even a slight measurement error can have a big impact.

What then do you do?

There are a number of probable causes, which is unfortunate if your digital scale is giving you inconsistent readings.

The 10 most frequent causes of inaccurate or changing weights, ranging from poor calibration to frequency interference, are listed in the following paragraphs.

1. INACCURATE CALCULATION

An incorrectly calibrated scale is one of the most frequent causes of inaccurate readings.

That’s because a scale’s accuracy can degrade over time due to normal use’s wear and tear.

Your scale needs to be calibrated if you’ve recently moved it or you notice that it’s not operating within the acceptable tolerance.

Verify that the calibration is within tolerance if you have test weights.

If you want to be sure your scale is operating properly, use our instruction on how to calibrate a scale.

The scale must be tested and its accuracy confirmed after calibration.

2. A UNEQUITABLE SURFACE

A scale may provide erroneous readings if it is set up on an uneven surface.

Because most load cells are not built to accurately measure a downward or sideways force, the force being recorded is no longer parallel with the direction of gravity.

Verify that your scale is balanced by using the levelling bubble and adjustable feet that are often included with scales.

If not, keep adjusting the feet until it is. Read our post on the significance of levelling a scale for more information.

3. AN IMPAIRED LOAD

The scale may provide erroneous readings if there is an imbalance in the weight that is being put on it. The scale may give an incorrect reading, for instance, if there is a heavy object on one side of the scale and a light object on the other.

This is because, despite the scale’s best efforts to balance the load, it is unable to do so due to the imbalance. We advise investing in a scale with a dynamic weighing feature if you frequently weigh animals or liquids.

4. AN UNSTABLE OR LOW BATTERY

Your scale may become progressively unpredictable and give false or shifting readings when the electricity in it starts to run out. This should always be one of the first things you examine when there is a problem because it is one of the most frequent causes of scale malfunction.

First, make sure the batteries are connected and charged properly. Replace the batteries or power adaptor if they can’t maintain a charge to see if that fixes the power issue. As a best practise, have extra batteries charged and accessible at all times as a backup.

5. MOISTURE OR WATER DAMAGE

Another typical issue that scale users may have is drifting. Drifting, which is typically brought on by exposure to water, is when a scale’s display fluctuates continuously. It is well known that unpredictable readings are brought on by water in the scale’s indication, junction box, load cells, cables, or internal components.

If water is found in the system, shut it down right away and let the scale completely dry. If there is no permanent damage, you might be able to use it once again. Use a scale with a high IP rating for maximum wetness protection if you’re working in a high-moisture area.

6. A RESIDENCE OR GRIME BUILDING

A bind could happen if there is too much dirt or residue on the scale. The collection of trash or foreign items under or around the scale might result in a bind, which stops the scale from receiving the proper amount of load. A piece of wood pallet getting wedged underneath a floor scale is a common illustration of this.

Remove the pan if you can so you can check for internal binds visually. If there is any debris, take care to remove it while observing the manufacturer’s instructions. Read our article on how to clean a balance for more advice.

7.DISTURBANCES IN THE ENVIRONMENT

Additionally, if a digital scale is exposed to a significant wind gust or even the smallest draught in a laboratory setting, it’s feasible that the scale will display inaccurate values. This is because when a force, such an air current, is applied to the scale, it cannot stabilise and cannot produce accurate measurements.

We advise taking your measurements indoors, away from any doors, windows, and air vents, if at all possible, to avoid this. It goes without saying that using a draught shield with your scale is the only way to be absolutely certain there won’t be any interference from outside air.

Environmental vibrations, such as an unsteady table, a moving workstation, or seismic rumblings, are another very frequent problem we encounter. If you’re truly committed to eliminating any chance of movement, you could wish to get an anti-vibration table.

8. DAMAGED or overloaded components

The measurements obtained from a digital scale that is overloaded might be inaccurate. This is due to the possibility that an overloaded scale will no longer be able to determine weight effectively. Read our article on what happens to a scale when it’s overloaded to find out more.

On the other hand, it is significantly harder to locate a damaged component. The mainboard, junction box, or even a faulty load cell could all be to blame. Another possibility is that the wires are not properly connected. Please get in touch with our technical support line if you need assistance troubleshooting damaged components.

9. SURFACING VERY HIGH TEMPERATURES

If a digital scale is subjected to excessive heat or cold, it could provide misleading readings. Since room temperature is the preferred condition for these devices, storing your scale in a chilly or damp environment could cause issues.

Particularly cold temperatures will draw moisture, which as we’ve already said might lead to issues inside the machine. Extreme cold can also slow down and inefficiently operate your equipment, which might have a detrimental impact on your results.

10. INTERFERENCE WITH FREQUENCY

Considering that digital scales are electronic instruments, they are not exempt from nearby radio frequency interference. For instance, a burst of static electricity, a cell phone, or a microwave can all impair the function of your scale.

This is due to the scale’s ability to give stable and accurate readings being susceptible to fluctuations in electromagnetic radiation from other wireless devices. To ensure your results are as consistent and precise as possible, always check your workstation and remove any surrounding gadgets before taking any measurements.

How do I fix an inaccurate scale?

In order to assure the accuracy of a weighing scale, the readings must be calibrated. The digital display or dial can be adjusted using known weights.

This is crucial in many fields where accuracy is crucial, like the food and pharmaceutical industries. To ensure accuracy and dependability, remember to routinely calibrate your scales. Anyone with the necessary training may easily calibrate your weighing scale.

CALIBRATE YOUR SCALE IN SIX STEPS

1.CLEAN THE WEIGHING SCALE, first.

To achieve accurate readings, it’s crucial to keep your weighing scale clean and well-maintained. Start by using a soft cloth to wipe the scale’s surface clean. After that, clean the scale platform with a mild soap and water mixture. Make sure to keep water off of the electronics.

2.Replace the batteries.

Even though changing the batteries is an optional step, it is best to make sure you are calibrating with completely charged or new batteries. In this manner, the method won’t be disrupted, and the process’ dependability is also guaranteed.

3. A FEW MINUTES PRIOR TO THE CALIBRATION, TURN ON THE SCALE

Digital scales must be powered on for a few minutes prior to the calibration operation. This allows the scale to warm up and stabilise, resulting in more accurate findings.

4. SET UP THE SCALE CORRECTLY

Keep in mind to maintain a stable scale position. The scale ought to be flat and placed on a firm, stable surface. If your floor isn’t level, level the scale by placing a thin piece of cardboard or a smooth stone beneath one of its corners. Unlevel platforms or weight plates will produce false readings.

5.PUT A “KNOWN” WEIGHT

Manufacturers of weighing scales include “known” weights in calibration kits with precisely measured and noted weights. They have certified weights that can be traced back to regional or global standards. They serve as benchmarks for calibrating scales and other measurement tools.

Simply place the “known” weight on the scale’s platform or plate, then read the reading. The scale must be modified until the two values line up, if necessary.

6.PUT THE CALIBRATED WEIGHING SCALE TO USE

You can use the scale after calibrating it. To ensure dependability and accuracy, however, remember to calibrate your weighing scale on a regular basis. If you have questions regarding the procedure, request calibration services from a respected scale supplier in your area.

SCALE CALIBRATION: WHY IS IT IMPORTANT?

Weighing scales experience wear and tear over time, which causes measurements to be off. Because of this, it’s crucial to routinely calibrate your scales, especially if you use them to measure building materials, pharmaceutical combinations, or food ingredients.

#ACCURACY AND PRECISION

It’s crucial to use a scale that is well calibrated if you need to measure something precisely, like while baking or cooking. The meal you serve will be of the proper weight, flavour, and quality if you do this.

#INCREASED EFFICIENCY

Using calibrated scales increases efficiency and productivity if you manage a company that depends on precise measurements, like a manufacturing plant or infrastructure. With the knowledge that your finished products and projects will be high-quality, long-lasting, and suitable for use by the general public.

#ADVANCED SAFETY

It can occasionally be dangerous to use an uncalibrated or incorrect scale. For instance, it’s crucial to utilise a correctly calibrated weighing device when measuring compounds for use in a pharmaceutical process to prevent unjustified user side effects.

#A higher level of customer satisfaction

A calibrated weighing scale is important if you sell items that must be weighed on a scale, such produce at a farmers market. This will help you make sure that your clients are satisfied with their purchases. For precise product weights, you will pay the appropriate purchasing price. Additionally, you won’t have to worry about selling your stuff for too much or too little money.

#CONFORM TO REGULATORY REQUIREMENTS

According to state laws, the majority of sectors need calibrated scales. For instance, there are tight regulations governing the usage of scales in the retail sector. You might have to use a scale that has been granted trade approval by your local government. You might need to research the National Trade Measurement Regulations of 2009 in this situation.

HOW OFTEN SHOULD YOUR WEIGHING DEVICE BE CALCULATED?

Scales should generally be calibrated at least once every three months. The setting in which it is used will determine how frequently it needs calibrating. Let’s assume that compared to scales discovered and installed in clean, dry settings, scales used in dusty or humid environments could need more frequent calibration.

The sort of scale you are using is another thing to take into account. A mechanical scale used in a harsh industrial setting could need a monthly calibration, yet a digital scale used in a controlled laboratory setting might only need an annual calibration.

While you can carry out the calibration on your own, there may be times when you need to rely on the knowledge of weighing scale providers to get the job done.

Why You Should Use a Kitchen Scale

I’ve started to include weight measurements whenever possible, as you may have seen. You might have even been a little irritated by this practise (as I did in the past). However, there is a valid rationale behind my decision to do this, and that is because measuring big quantities of anything other than liquids with volumetric measurements (cups, tablespoons, and teaspoons) is incorrect.

Volumetric measurements have been utilised incorrectly for a long time, giving the impression that they are accurate when they are actually grossly erroneous. Using flour as an example. There is a lot of air between each wheat particle in the loose powder. The amount of flour that can fit into a cup is significantly altered by the fact that it may be crushed. You can be adding either too little or way too much to the dishes you prepare depending on factors like your angle of approach, the power with which you scoop, and the shape of the measuring cup.

I experimented with scooping 1 cup of flour with the same cup while varying the power and angles of approach to test this. The largest cup of flour weighed 201 grammes, while the lightest cup weighed 157 grammes. The amount of flour metered out using the same cup differs by 28% in this instance.

For leafy goods like herbs, which are frequently measured volumetrically or, worse yet, by approximation, the variations can be significantly greater. Does a quarter cup of basil indicate that it is loosely packed or that it is so tightly packed that there is no air between the leaves? How big should the leaves be if it’s loosely packed? varied leaf sizes will settle with varied degrees of looseness. And what does a thyme sprig or a bunch of parsley even mean? What size is a sprig? How large are your hands? Are you still perplexed?

Then there are foods like onions and tomatoes. I’m not sure about you, but they come in a large range of sizes the last time I looked. In a world where there are cherry tomatoes that are the size of a pea, melon-sized heirloom tomatoes, and everything in between, using terms like “small” or “large” is almost meaningless.

Here are my top five justifications for why your kitchen needs a digital scale.

1.They are more precise

Volumetric measurements are unreliable for all the reasons mentioned above, with the exception of liquids.

2.They are simple to use.

If you’ve never used a digital scale, you should know that it’s an entirely different experience. They include sizable digital displays that instantly show you the precise weight of your item. You may zero out the scale by placing a bowl on it using the tare button. You can place the bowl on the scale, tare it, and pour each ingredient directly into the bowl if a recipe calls for 250 grammes of flour, 10 grammes of yeast, and 5 grammes of salt without ever using a measuring cup or spoon.

3.They convert things.

The majority of digital scales have simple metric to imperial conversion features. While utilising a digital scale eliminates the necessity for conversions, the metric system is typically simpler to use than the imperial system, especially when working with little quantities (0.17637 ounces of salt vs. 5 grammes of salt).

4.They’re affordable

Digital scales are affordable; the entry-level models cost around $50.

5.They are little

I am aware of how difficult it can be to choose which kitchen tools to keep because of space restrictions, yet digital scales are just little larger than a tiny paperback book.

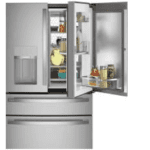

Whic is the best weighing scale for kitchen?

How do home scales work?

Your weight is determined by a conventional scale based solely on physical load. Contrarily, a body composition scale uses bioelectric impedance analysis to estimate how much of your overall weight is made up of body fat and how much is fat-free mass. met as the body’s electrical current passes through it.

The bending of the transducer beams results in a change in electrical resistance when an object is placed on the weighing platform of a digital scale. An Analogue to Digital (A/D) Converter measures the variation in electrical resistance; it then communicates the reading to the microcontroller via the circuit board of the device.

How much food weight is normal?

According to studies, the typical human consumes three to five pounds of food per day. The Centres for Disease Control and Prevention (CDC) states in a booklet titled Low-Energy-Dense Foods for Weight Management: Cutting Calories While Controlling Hunger, “Research suggests that people eat a pretty consistent amount of food on a daily basis.

Read More – How to Use a Salad Spinner

3 thoughts on “Why are digital kitchen scales so unreliable? 10 REASONS FOR INACCURATE OR FLUCTUATING WEIGHTS – Best Home depot”